PERFORMANCE-BASED DESIGN

Optimizing Fire Safety in Complex Buildings with CFD and Evacuation Simulation: Flowpak’s Solutions

In designing larger and complex buildings, compliance with prescriptive codes such as Qatar Civil Defense and NFPA for fire life safety can present significant challenges and costs.

A performance-based design engineering approach is employed to mitigate this, utilizing established engineering tools, methodologies, and performance criteria to meet design goals and objectives.

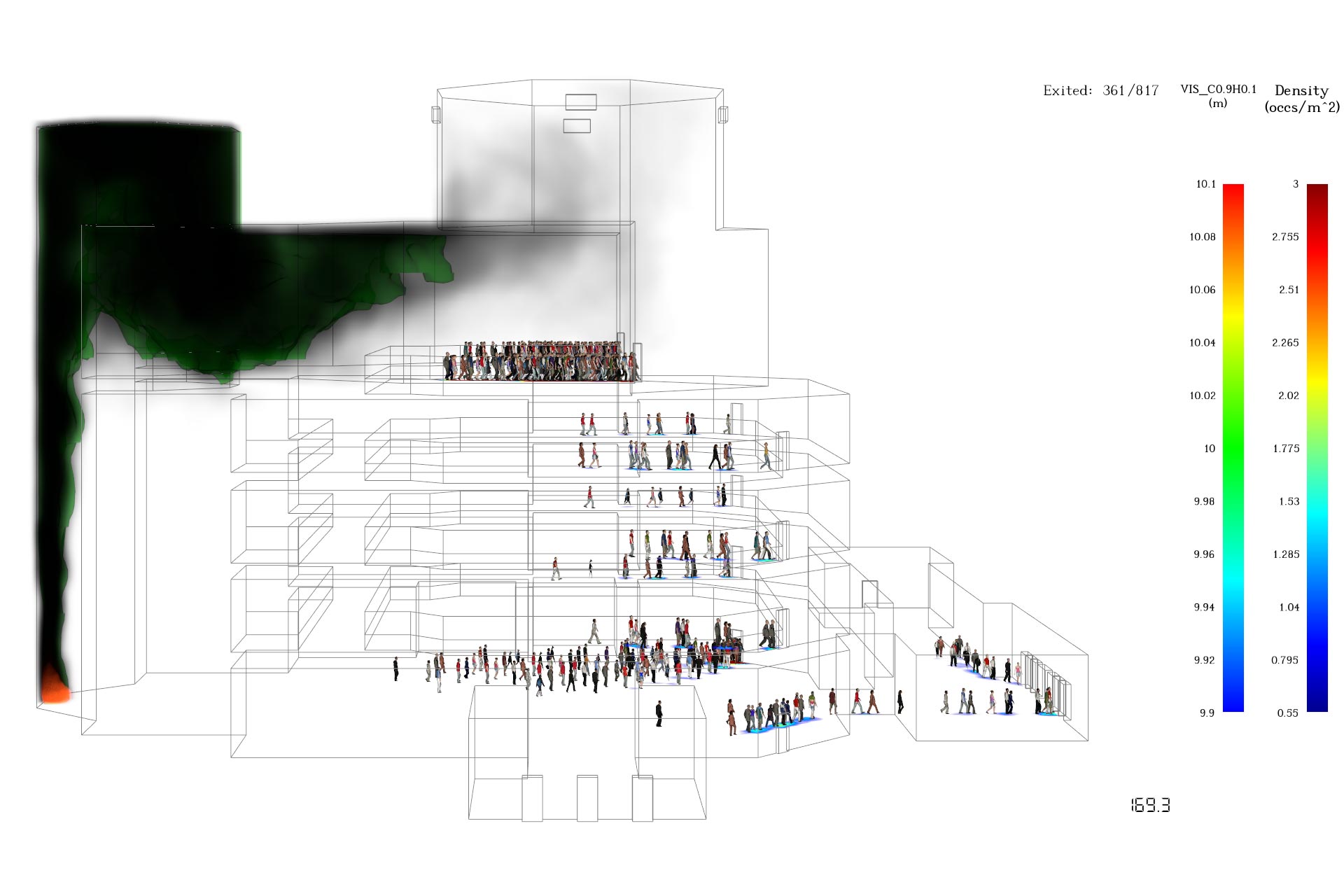

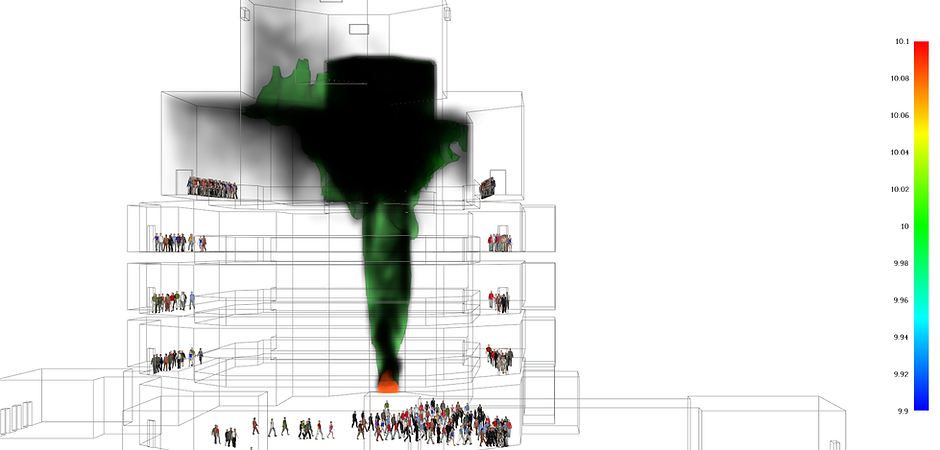

To optimize the building’s fire life safety design, Flowpak engineers utilize computational fluid dynamics (CFD) software to simulate the behaviour of smoke and heat during a fire event. Moreover, evacuation simulation software is also employed by Flowpak experts to model human behaviour during an evacuation, enabling the optimization of evacuation routes and egress strategies and ensuring that the building’s design facilitates the safe and efficient evacuation of occupants in emergency situations.

Flowpak’s Performance-Based Design Engineering for Fire Safety at the Museum of Islamic Art in Qatar’s Complex Building

In the design of the Museum of Islamic Art in Qatar, it was crucial to ensure that the available safe egress time (ASET) is greater than the required safe egress time (RSET).

The ASET is the amount of time from ignition to the onset of untenable conditions, and the RSET is the amount of time following ignition, after which all the occupants can leave the fire-affected space and reach a place of safety.

If the ASET is less than the RSET, the occupants will not have enough time to evacuate the building before conditions become untenable.

In the case of the Museum of Islamic Art in Qatar, Flowpak engineers used a performance-based design engineering approach to optimize the building’s fire life safety design.

This approach involves using computational fluid dynamics (CFD) software to simulate the behaviour of smoke and heat in the event of a fire and evacuation simulation software to simulate people’s behaviour during an evacuation. These tools were used to determine the ASET and RSET for the building, and the engineers used this data to optimize the building’s design and evacuation routes to ensure that the ASET was greater than the RSET.

Furthermore, the unique design and architecture of the Museum of Islamic Art required a different approach to fire safety; the engineer’s used performance-based analysis to ensure that the building’s design met the required safety standards while also preserving the architectural integrity of the building.

By utilizing the performance-based design engineering approach, the Flowpak engineers were able to create a fire safety solution that is both safe and appropriate for the specific building.

Meeting Unique Smoke Management Challenges in Prisons with FDS and EVAC Modeling: Flowpak’s Effective Solutions

Prisons present distinct challenges compared to other types of structures, such as atria, regarding smoke management during fire incidents due to variations in fuel load and building configurations.

Specifically, the fuel load in prisons is heavily regulated as a result of institutional operations, whereas fuel loads in other spaces may be more varied.

Additionally, the architectural layout of prison cell blocks, characterised by relatively small and compartmentalised spaces, contrasts with the expansive and multi-level design of atria.

The use of FDS and EVAC modelling by the Flowpak consultant team played a critical role in ensuring the safety and compliance of the smoke management system for the prison located in the UK.

It also helped in providing the prison management with confidence in the system’s ability to effectively manage smoke during a fire incident and protect the lives of inmates and staff.

Flowpak’s Engineering Analysis of Metro Station using ASET/RSET in Compliance with NFPA 130

In accordance with the National Fire Protection Association’s (NFPA) 130 standard for Fixed Guideway Transit and Passenger Rail Systems, a metro station‘s design must ensure evacuation from the farthest point on the platform to the point of safety that can be achieved within six minutes or less.

The evacuation times and travel distances may be adjusted based on an engineering analysis that takes into account factors such as material heat release rates, station geometry, and emergency ventilation systems.

In this scenario, Systra, a company involved in rail engineering, engaged Flowpak to validate a smoke control system strategy for a metro station in the Middle East by conducting an Analysis of Safe Evacuation Time (ASET) and Required Safe Evacuation Time (RSET) analysis.

This analysis helps evaluate the station’s evacuation time and capacity during a fire event and identify potential issues or improvements to the smoke control system.